2025 Steel Fabrication Projects In Review

At DWW Engineering, 2025 has been a year defined by strong partnerships, technically demanding work, and consistent delivery across a diverse range of sectors.

Expanding Our Work with Evolution Mining

Our long-standing partnership with Evolution Mining continued with the delivery of multiple underground mining grizzlies to the Ernest Henry operation. Supplied as fully assembled kits complete with fasteners, these units were designed to simplify site installation and minimise downtime. With this year’s deliveries, the total number of grizzlies produced for Evolution now stands at 20 – each one built for durability and performance in demanding underground conditions.

Read the original case study.

Precision Fabrication for GEARS Mining

We also completed another fabrication project for GEARS Mining, supplying high-stress steel components for a mill reliner handler. These parts, engineered to withstand extreme operational forces, are critical to safer and more efficient mill maintenance. Our ongoing relationship with GEARS reflects DWW Engineering’s ability to deliver consistent, quality results for the mining sector.

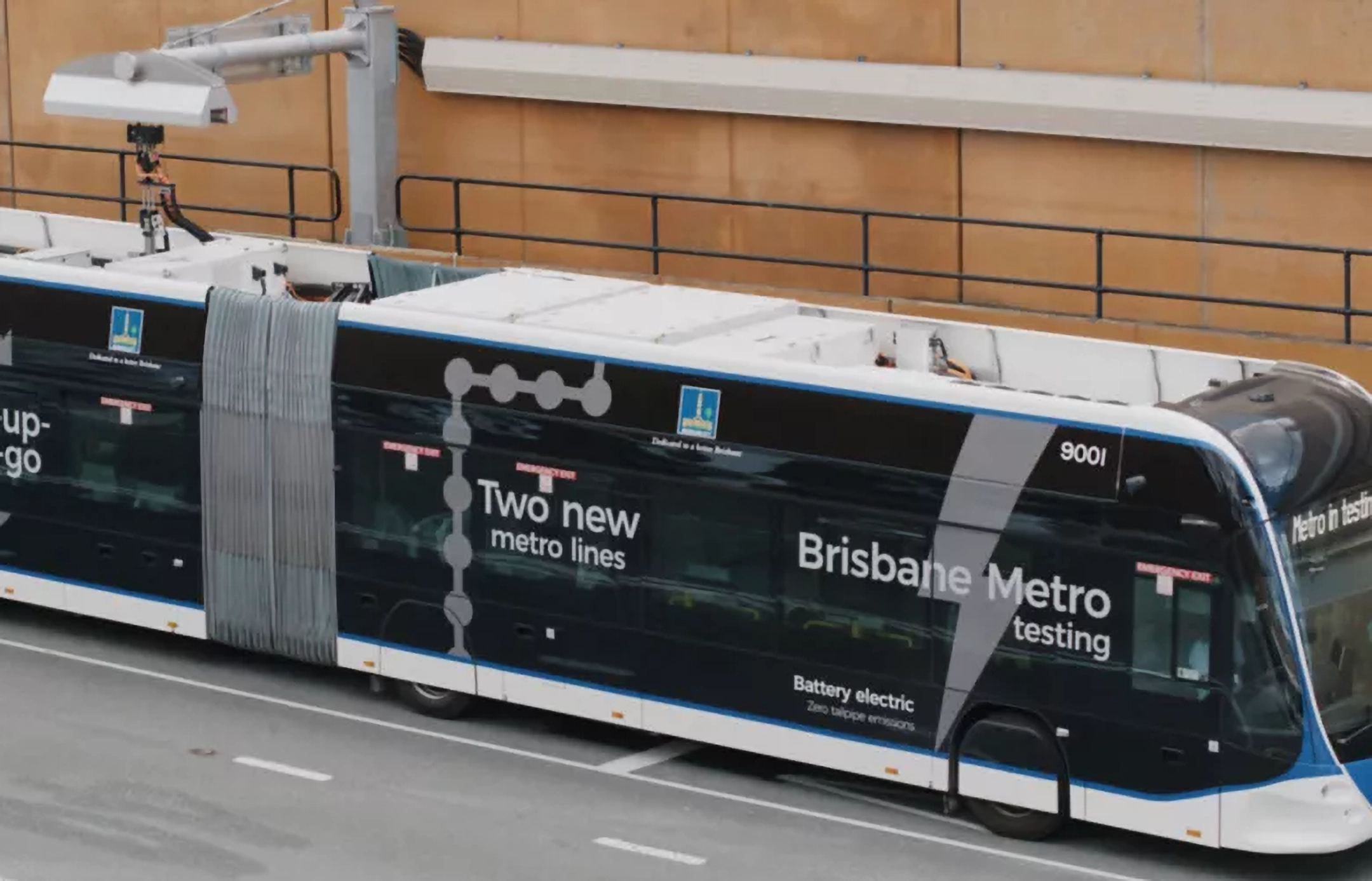

Supporting Brisbane’s Electric Transport Future

As Brisbane transitions to more sustainable transport, DWW Engineering contributed to the Brisbane Metro project by fabricating overhead charging gantries for the new electric bus fleet. Delivered in partnership with Hitachi, these gantries were fully designed, trial-assembled and prepared in-house to ensure smooth site installation. It’s a project we’re proud to be part of, helping future-proof public transport in the city.

Formwork Solutions for Civil Infrastructure

On the civil infrastructure front, we fabricated and trial-assembled steel formwork for a sewage pumpwell system in a residential development. Engineered for a 5.5 m internal and 6.3 m external diameter, and supplied in two pre-assembled 1.5 m high sections, the system was packaged and ready for pick-up ensuring ease of installation and dependable performance on-site.

A Year of Capability, Consistency and Sector Expertise

These projects showcase DWW Engineering’s ability to manage the full fabrication lifecycle – from engineering and drafting through to trial assembly and delivery. Our projects this year have strengthened our position as a trusted partner across the resources, power, infrastructure, and industrial sectors.

As always, we remain focused on delivering precise, practical solutions—built to last and designed to fit the way our clients work.

We look forward to continuing the journey in 2026.