Why Substation Steel Decides Grid Reliability

When people talk about power system risk, they usually jump straight to generation, system strength or protection schemes. The structural steel quietly holding everything up rarely gets a mention. Yet in high voltage yards, towers and substation structures, a single poor decision in substation steel manufacturing can ripple through to safety incidents, outages and long-term reliability problems.

Structural steel fabrication is no longer a commodity line. It is a live grid risk that needs to be managed as carefully as any primary plant or protection relay.

Why lattice towers and support structures matter more than ever

Across many networks, the predominant structure type is the double circuit lattice tower, with lines designed to AS/NZS 7000 Overhead Line Design and associated Australian standards, with an expected service life of around 50 years. These structures stand in varied terrain and climate, absorbing wind, conductor tension, construction loads and maintenance activities over decades.

In substations, steelwork supports everything that makes a yard function. Equipment support structures, gantries, cable ladder supports, maintenance platforms and access systems all sit under the umbrella of AS 2067 for high voltage substations, AS/NZS 1170 for structural actions, and related utility standards.

For a tower manufacturer or specialist tower fabricators, that standards stack is not theoretical. It defines clear expectations around strength, clearances, corrosion protection and service life. Any shortcut in design, detailing or fabrication undermines assumptions made by system planners and network standards.

What poor fabrication really looks like on site

Common failure modes when steel structure fabrication is treated as a low value package include:

- Out of tolerance fabrication: Bolt holes off by a few millimetres on a tower leg or substation structure translate into site reaming, packers, forced tolerances and lingering questions over capacity under extreme wind or conductor loads.

- Distortion and lack of fit: Inadequate jigs, poor welding sequences or rushed fabrication can twist members just enough that nothing lines up cleanly in the field. Crews end up cutting, heating or forcing assemblies during tightly planned outages.

- Non-compliant welds and missing traceability: Weld procedures, welder qualifications and inspection records that do not align with AS/NZS 1554 or project specifications leave owners exposed if a structural failure is investigated.

- Coating system shortcuts: Incorrect surface preparation, film thickness or curing control on galvanised or painted components shortens asset life and feeds back into higher maintenance budgets.

For delivery partners, these issues translate directly into:

- NCRs and rework while the clock runs on outage windows

- Extra crane and crew time that was never allowed for

- Extended exposure to live plant and construction risk

- Pressure from regulators and safety teams if an incident occurs

- Reputational issues when communities and large users experience unplanned outages

How precision fabrication supports grid reliability

High quality substation steel manufacturing is not just about having modern machines on the floor. It is about how those machines, people and processes are working together to fabricate quality structures, that are compliant, reliable and fit the first time.

Key elements that matter:

- In house detailing aligned to standards and client design packs

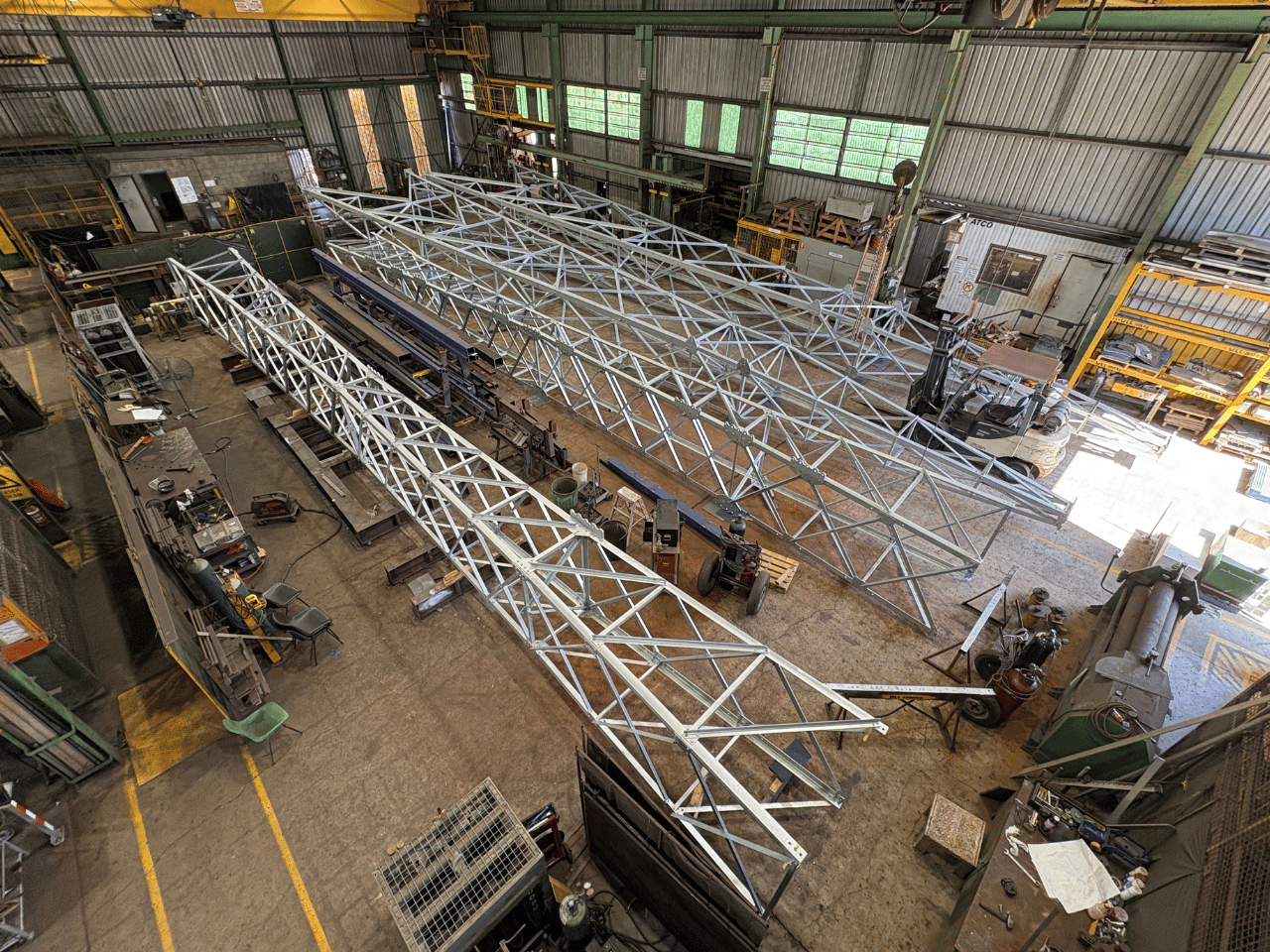

Structural models and drawings that reflect quality and utility specific standards such as substation and line design requirements, rather than generic industrial assumptions. - CNC drilling and fit up accuracy

Automated drilling and cutting, combined with controlled jigs and fixtures, hold tolerances so that towers, gantries and equipment structures bolt together cleanly in the field. That reduces hot work, reaming and ad hoc fixes under time pressure. - Controlled welding procedures and inspection

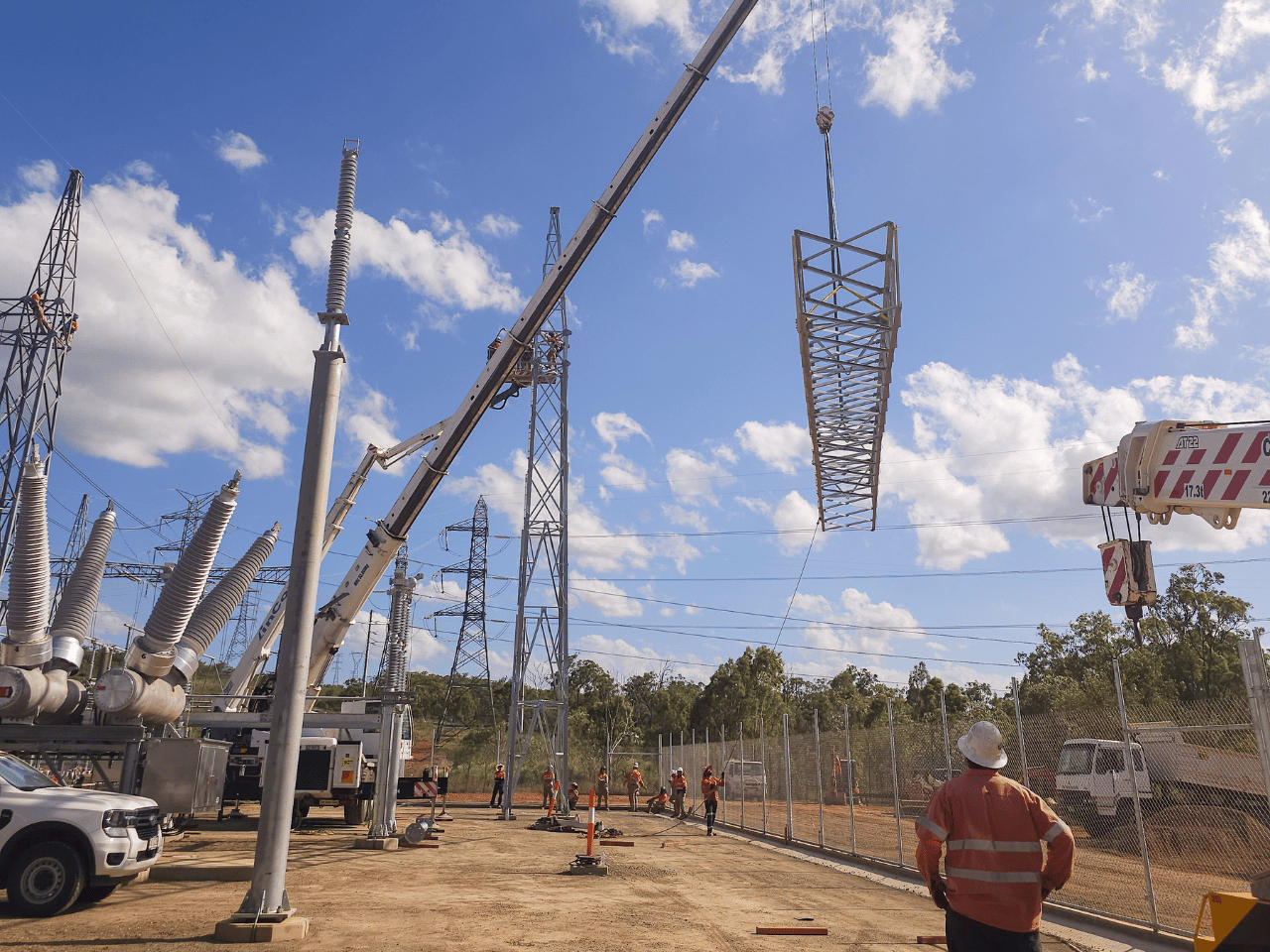

Qualified procedures, coded welders and systematic VT, MT or UT where required support long term performance in cyclic loading and dynamic environments. In high voltage yards, this is as much a safety barrier as any interlock. - Trial assemblies for critical structures

For complex lattice structures or new substation steel designs, trial erection in the workshop catches clashes and fit up issues before anything hits a remote site. - Material traceability and documentation

Mill certs, coating records, ITPs and as built documentation packaged in a way that suits utility and EPC QA systems. When an audit or incident review occurs, the steelwork is not the weak link.

DWW Engineering’s role as structural steel manufacturers is to bring this level of control to each project, so site teams can focus on safe installation and commissioning rather than solving fabrication problems in the mud.

Modular, repeatable substations for a renewable heavy grid

Across both regions, the transmission landscape is shifting from singular infrastructure upgrades to system-wide transformation. The energy strategies for Queensland and New South Wales emphasise extensive generation and storage deployment, alongside major transmission reinforcements and new switching stations. In that environment, substation steelwork must not only be robust, but it must also be modular, repeatable, and engineered for scalability.

Why modular and repeatable designs matter now:

- With multiple planned substation upgrades and new switching yards, a one-off fabrication model slows progress and introduces risk.

- Standardised details (splice plates, bolt-patterns, access platforms) reduce on-site assembly time, which is critical when outages or commissioning windows are tight.

- Project staging is more common: build a basic substation now, then add battery systems, extra transformer bays or renewable feeder connections later. Modular structural steel allows for “future-bay” capability without major rework.

- Many sites are in constrained or remote locations. A repeatable steel package means faster mobilisation, fewer surprises and simpler logistics.

What to demand from your steel partner

As transmission projects accelerate, the quality of substation steel directly affects outage duration, safety, commissioning schedules and long-term grid reliability.

A capable fabrication partner should demonstrate:

- Experience working to industry quality standards and utility specific standards

- Proven delivery of lattice towers, gantries and substation structures for power clients, not just general industrial work

- In house detailing that supports clash free installation in crowded brownfield yards

- Clear QA systems, including welding procedures, NDT and full traceability

- Coating systems suited to coastal, industrial and remote inland environments

- Capability to support remote site installations and respond quickly if issues arise

- A mindset that treats grid outages, commissioning milestones and regulator expectations as shared constraints, not “client issues”

DWW Engineering operates as one of the structural steel fabricators that understands these pressures. The goal is simple: deliver steelwork for substations and lines that installs cleanly, passes inspection the first time and performs for the full asset life.

Bringing fabrication into your risk conversation

High voltage projects are only getting more complex, and the scrutiny around safety, construction quality and outage performance isn’t going anywhere.

Treating substation and transmission steelwork as part of your project’s risk management, not just procurement, helps protect schedules, avoid rework and support long-term network reliability.

For teams delivering infrastructure, DWW Engineering bringing a capable steel fabrication partner into the conversation early makes construction smoother, installation safer and the finished asset more dependable over its full service life. Contact us to discuss your project requirements.