Substation Expansion for BES Site

Client: Transmission System Operator

Application: Substation expansion

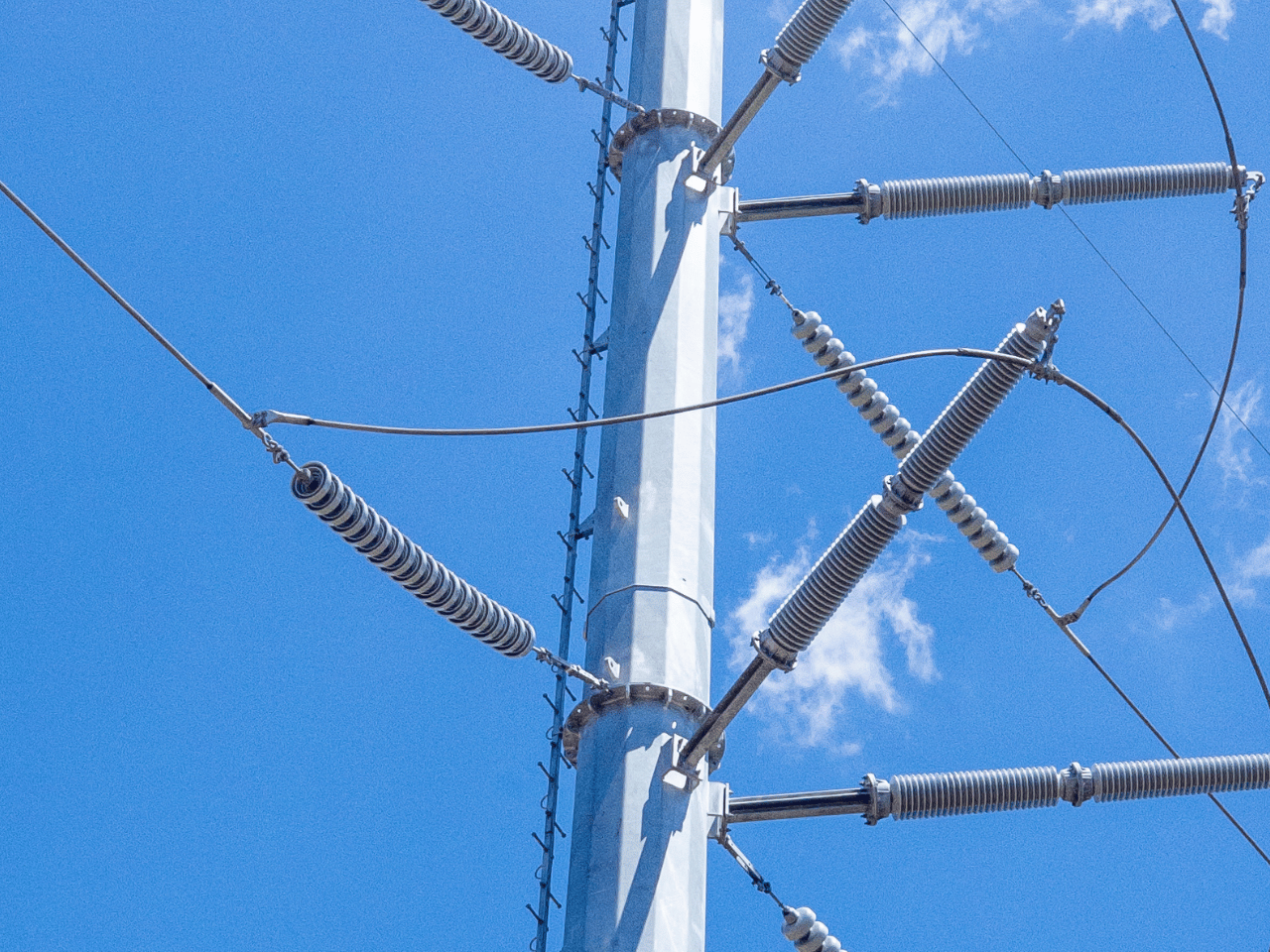

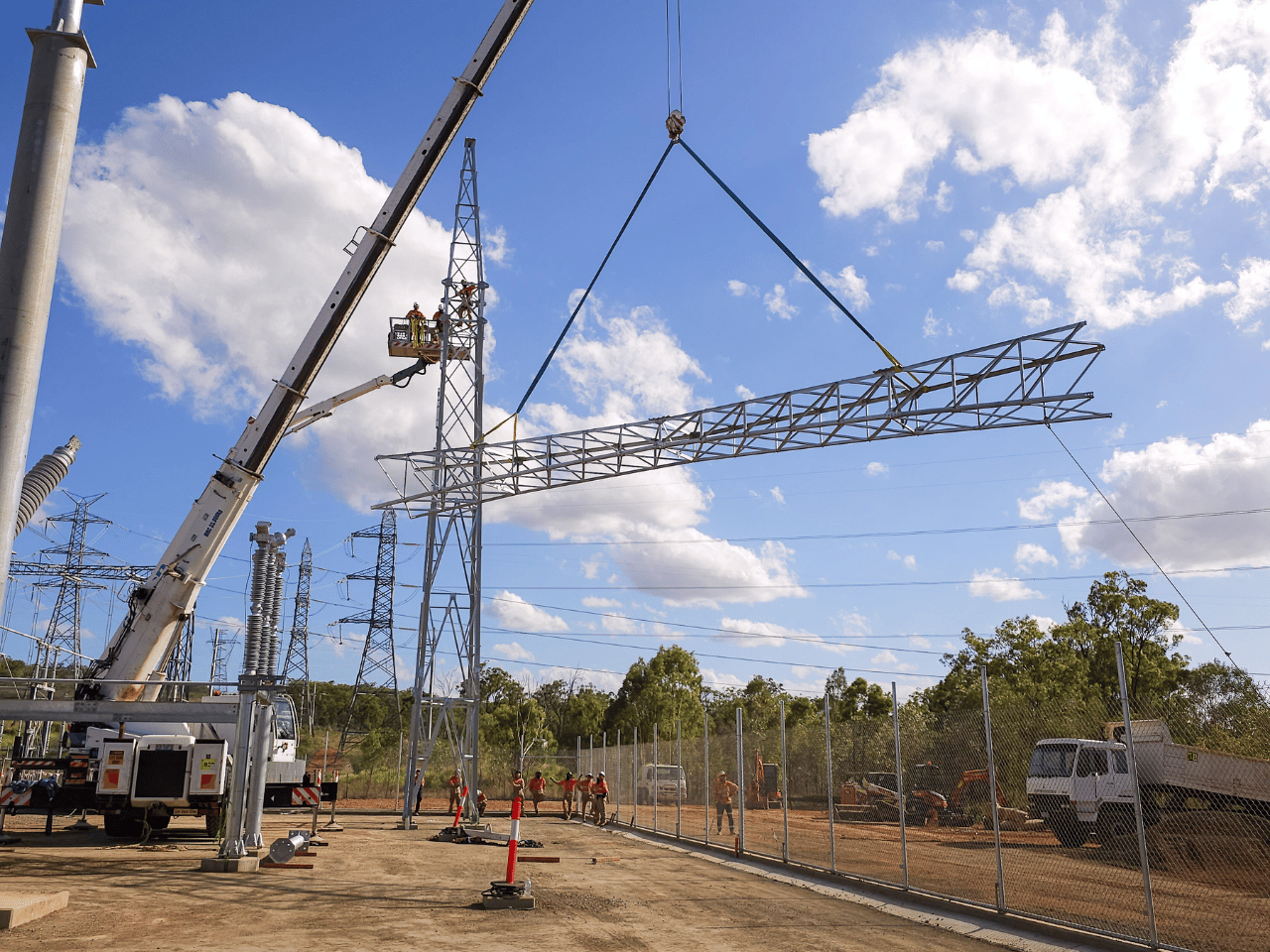

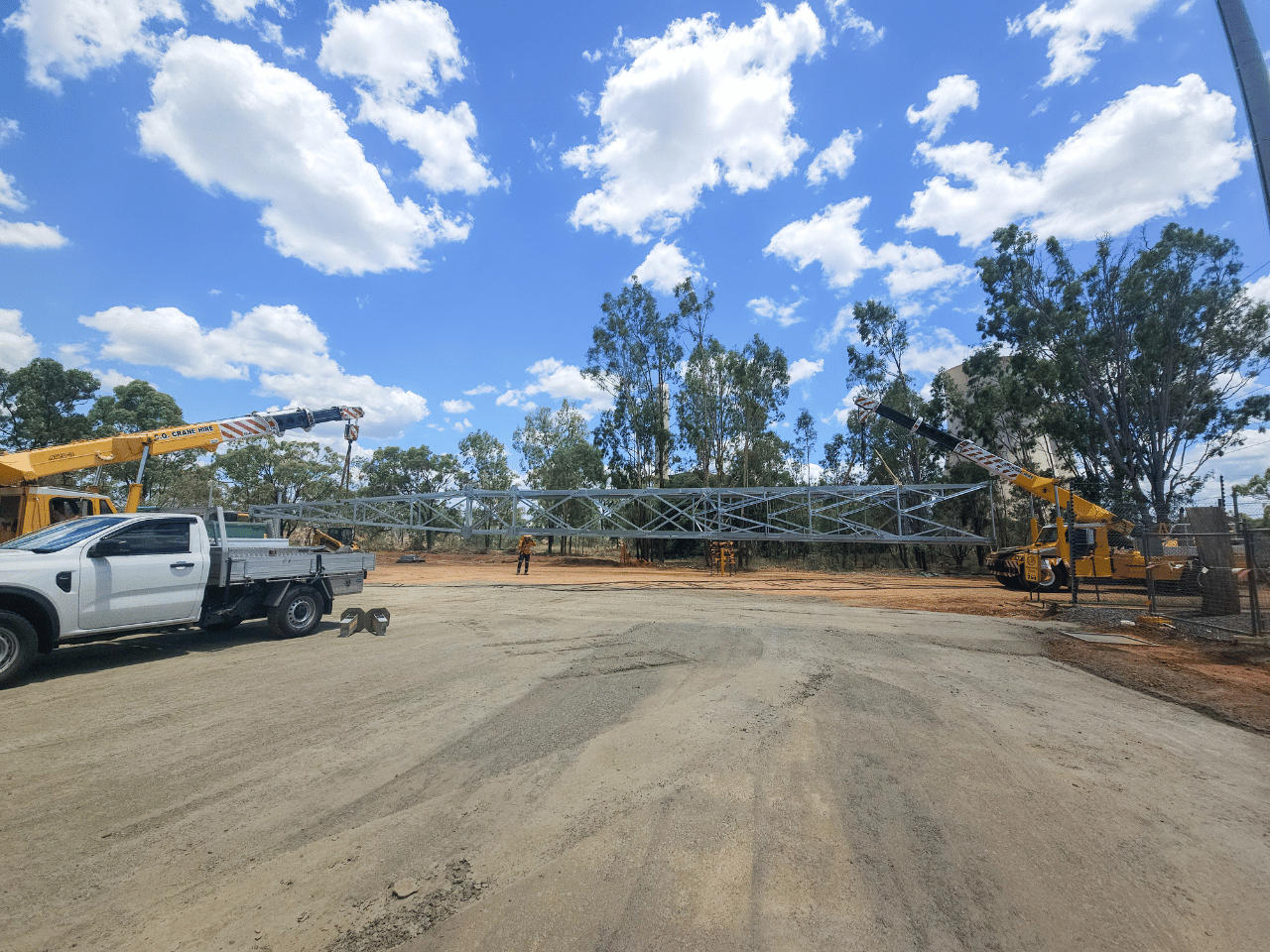

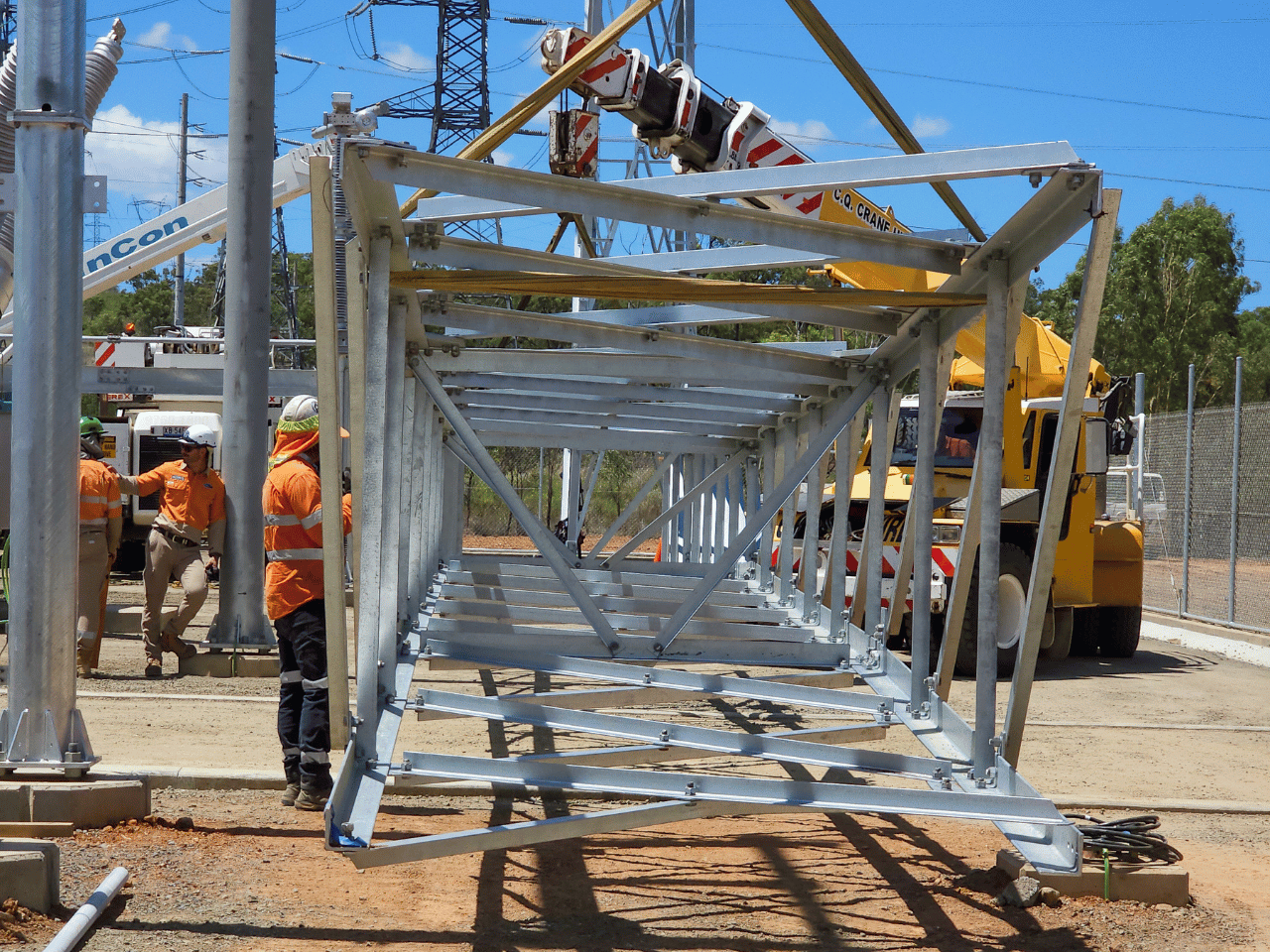

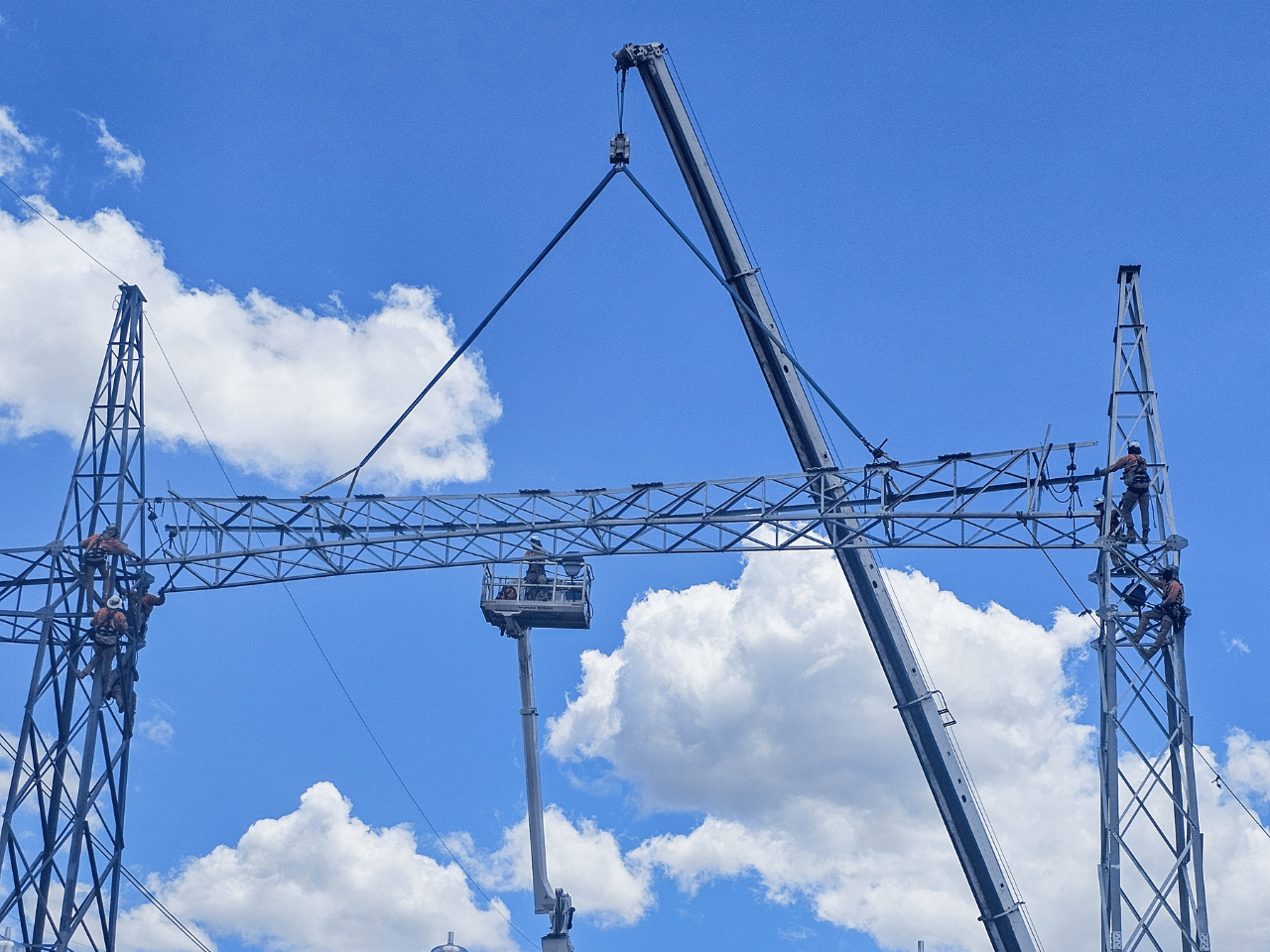

Scope: Fabrication, preassembly, delivery and installation of two lattice towers and suspension beams

Project Details

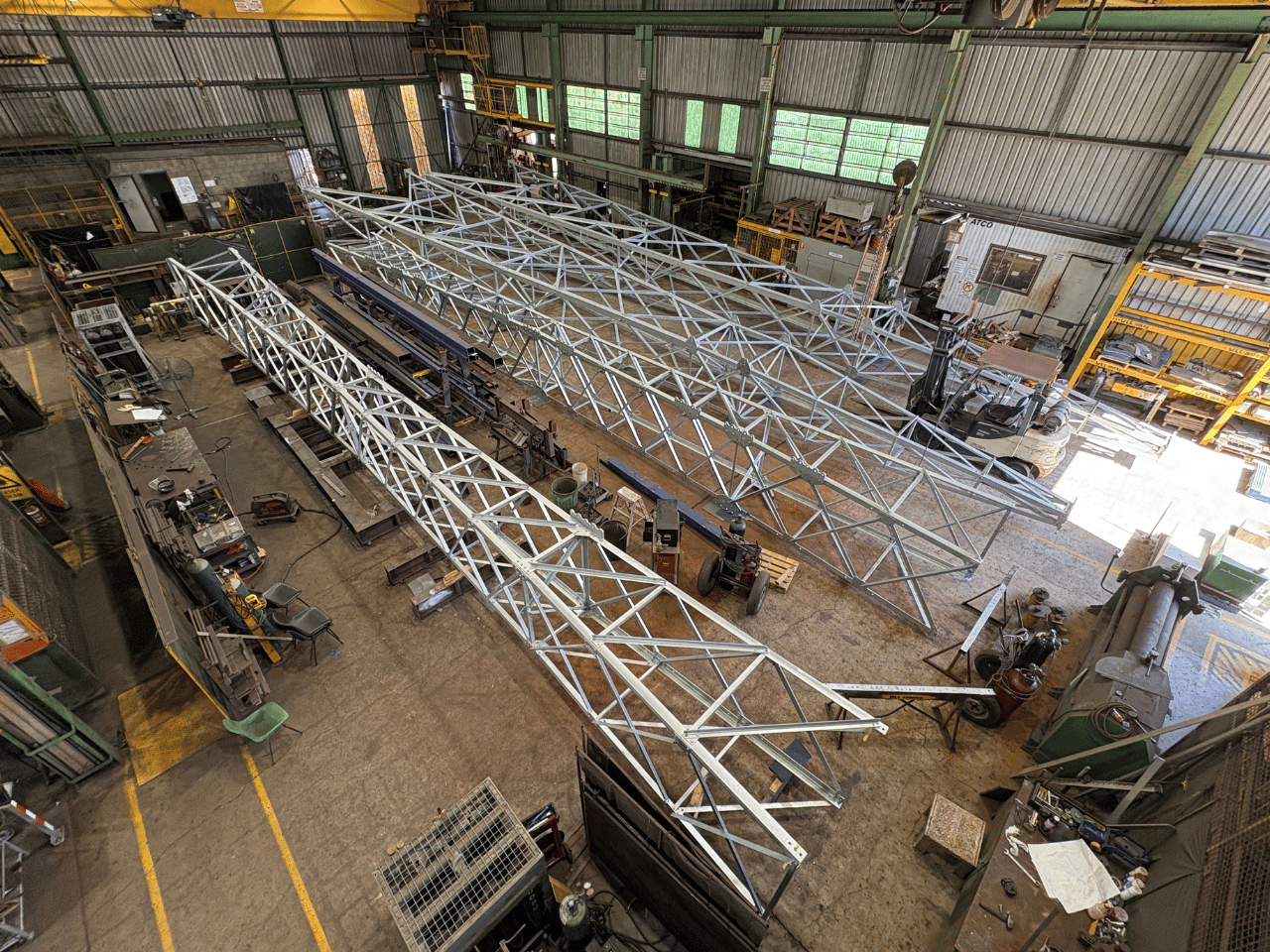

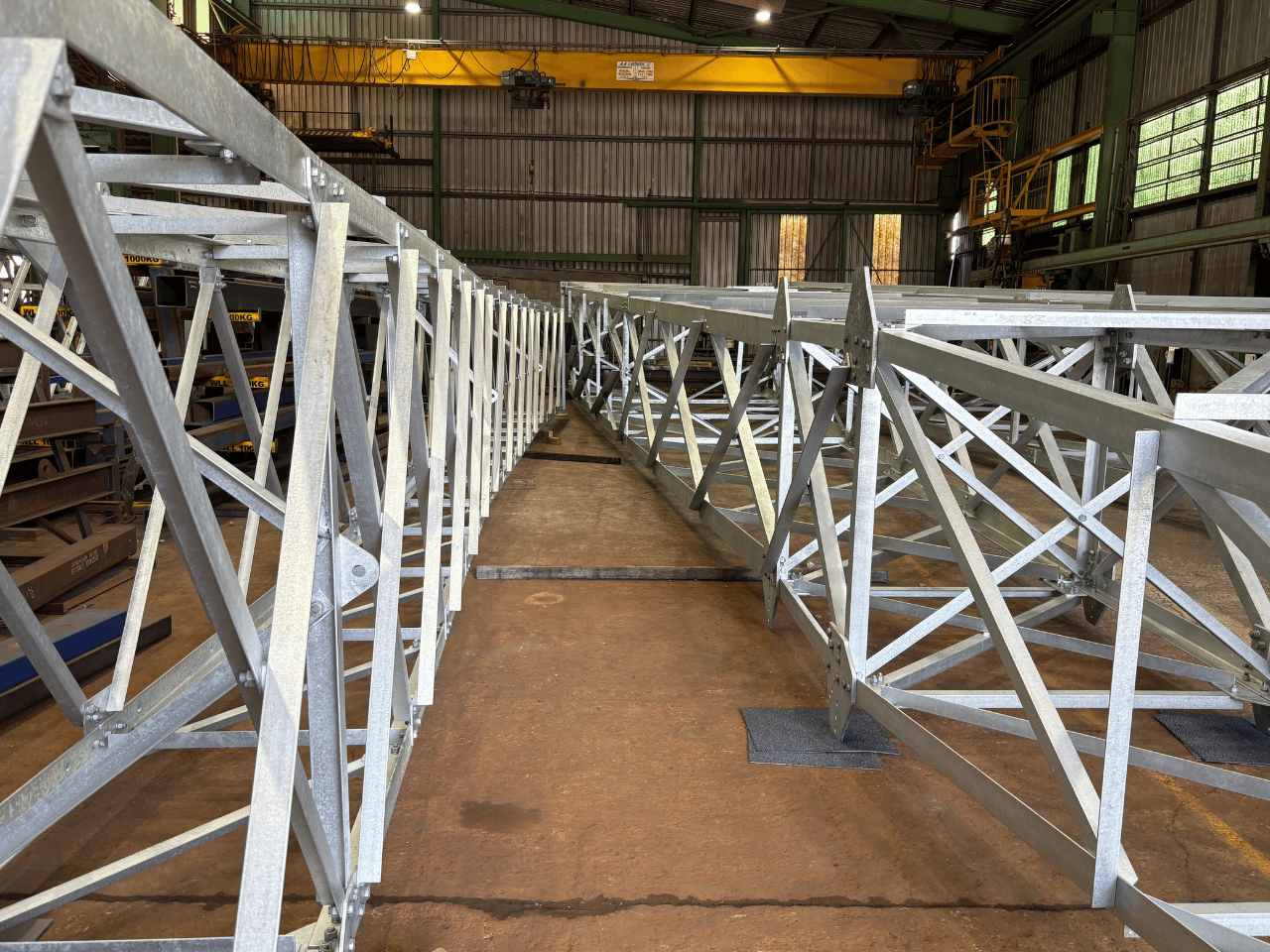

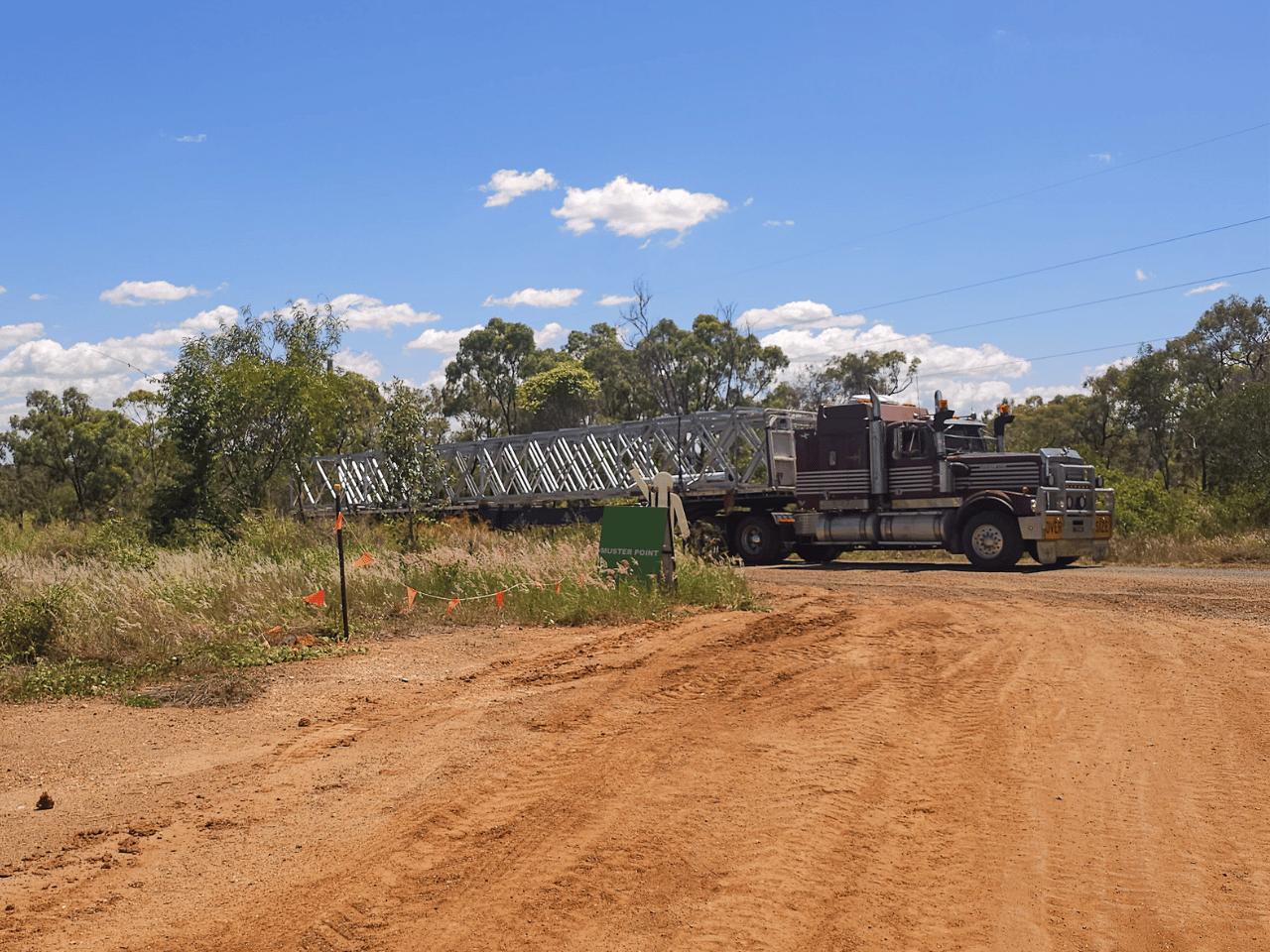

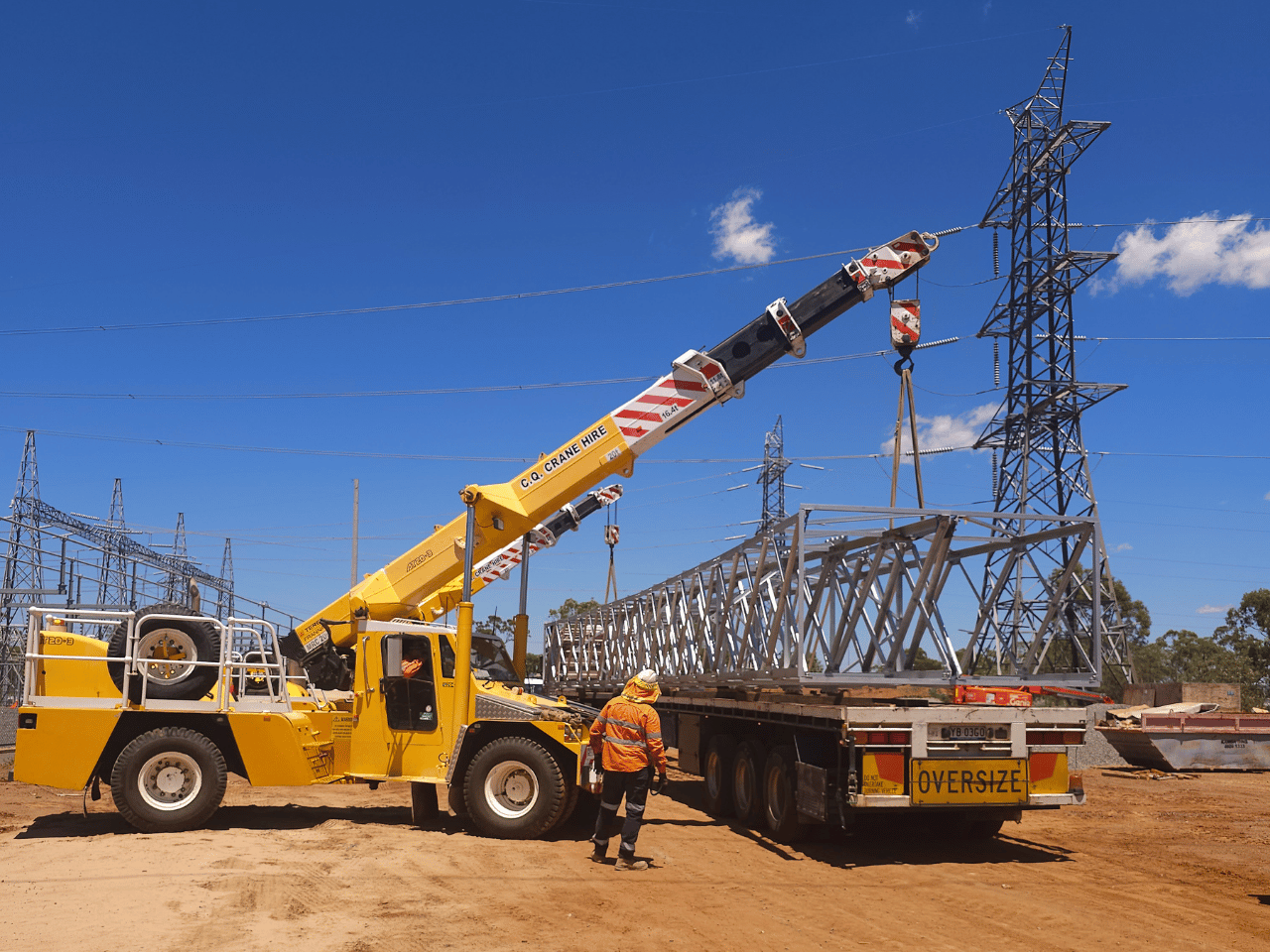

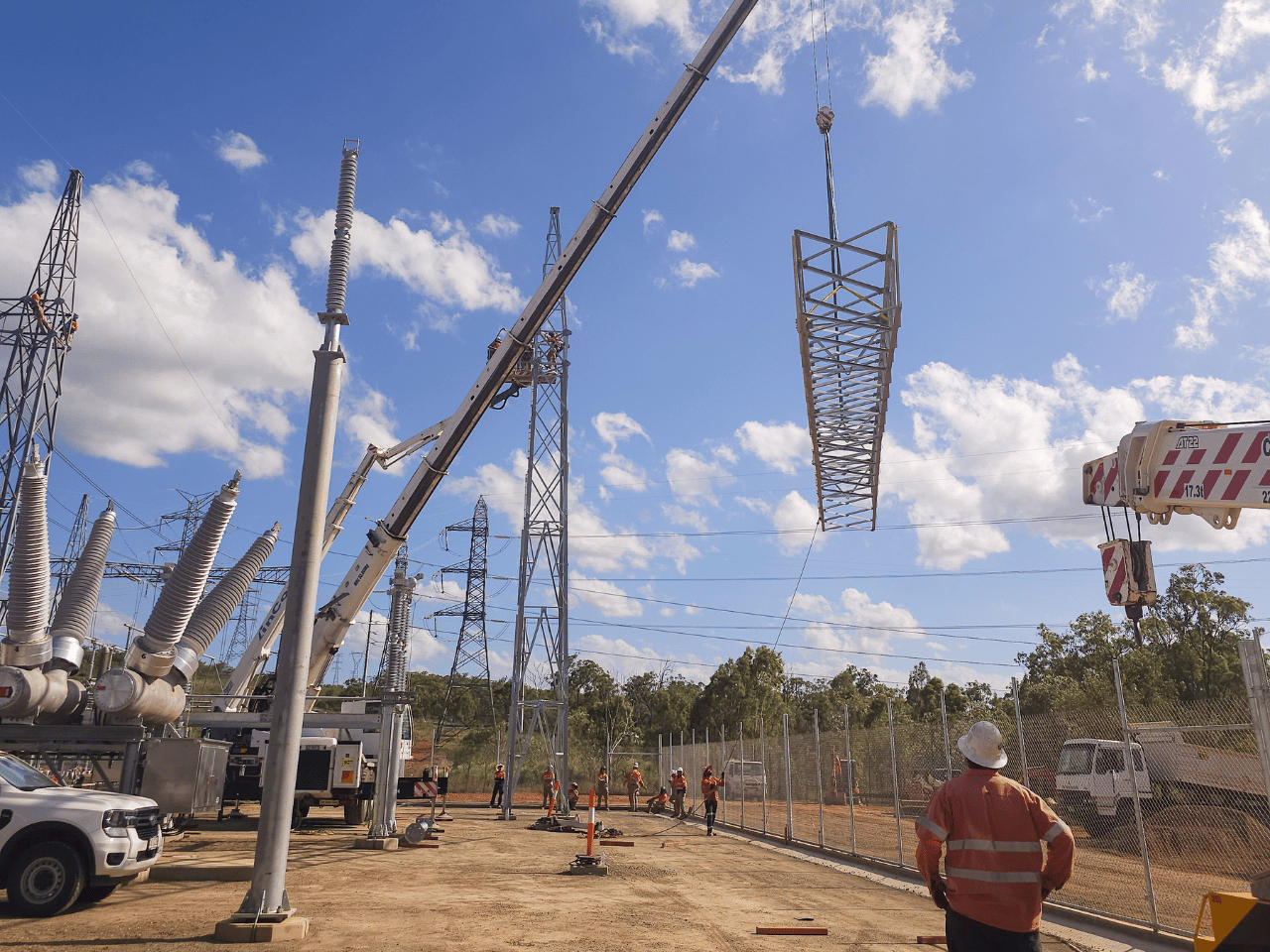

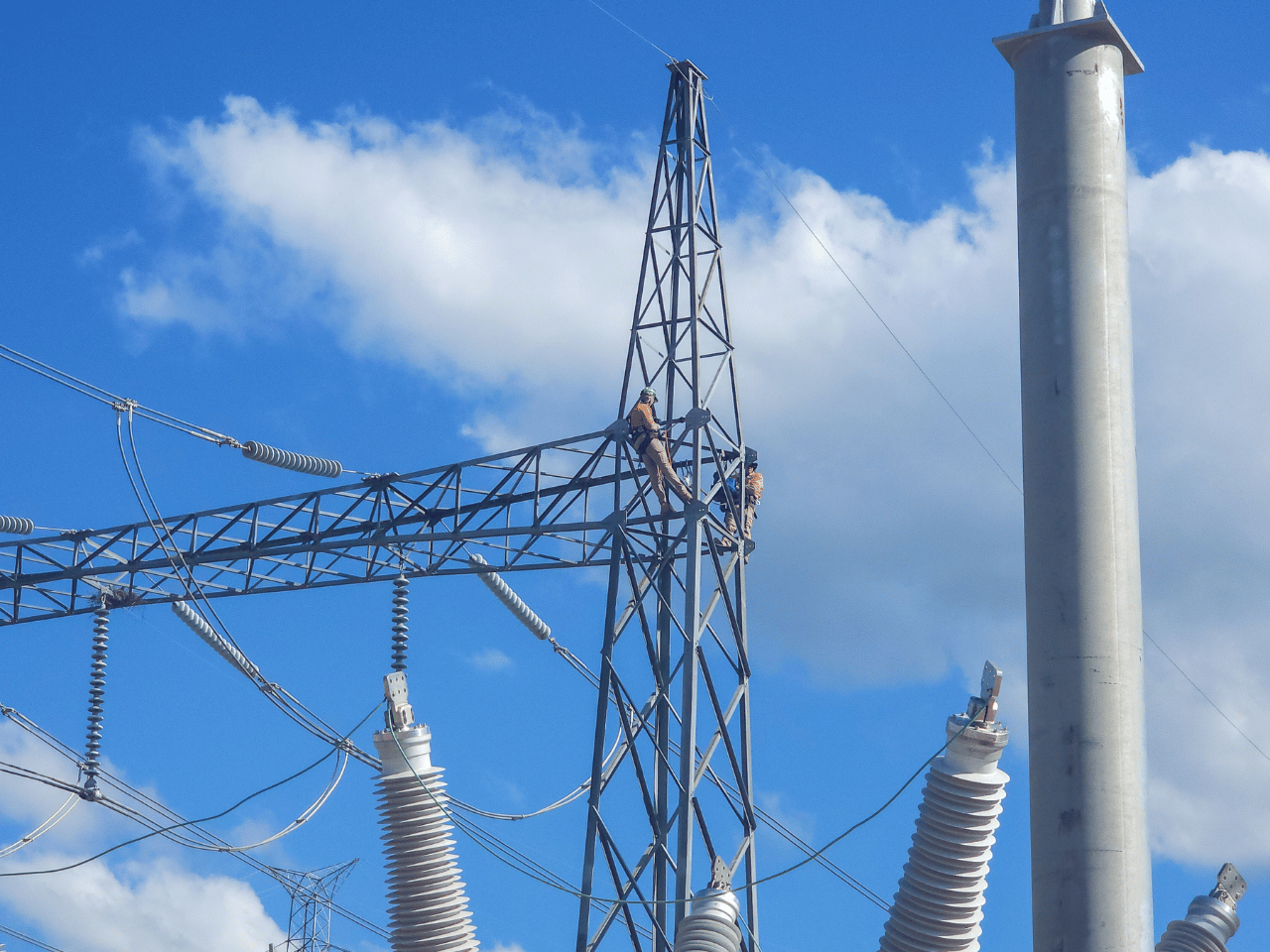

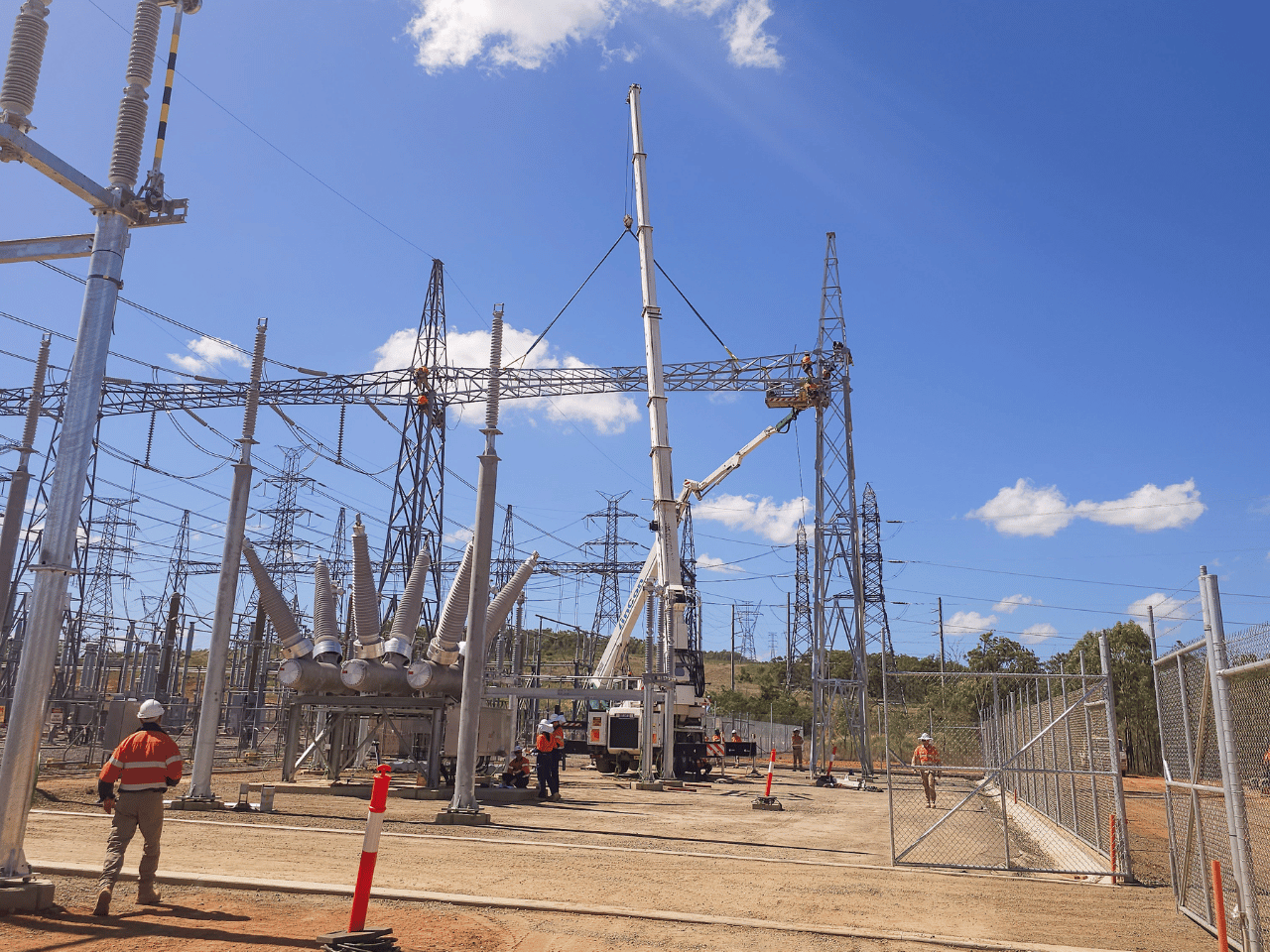

DWW Engineering recently delivered a full substation steel package for a site in Central Queensland to expand the substation for a BES (battery energy storage) project. The project included the fabrication, galvanising, assembly, delivery and installation of two 24 metre lattice towers, and two suspension beams – all fabricated to exact tolerances. DWW Engineering completed the entire fabrication and assembly process for this project in a mere eight weeks, as the client was working within a tight timeframe.

To ensure a perfect fit on-site, the entire structure was pre-assembled in our Darra workshop. This approach confirmed alignment with foundation bolts and eliminated the need for on-site rework. Once assembled, the components were delivered fully assembled and installed on site by our team.

Highlights

- Fabrication and assembly of entire project within eight weeks.

- Pre-assembly in Darra workshop ensured all components were fully fitted and checked before transport.

- Installation of lattice towers and beams on-site.

- Exacting tolerances were maintained to guarantee structural alignment with foundation bolts on-site.

- No rework required on-site, reducing installation time and risk.