Choosing the Right Formwork System for Complex Civil Projects

Here’s what to consider – and why steel often stands out when the job demands accuracy, repeatability, and performance.

1. Understand the Project Complexity

Start by identifying what makes the project complex. Standard formwork systems might be fine for typical slabs or walls, but civil infrastructure often brings a unique set of challenges:

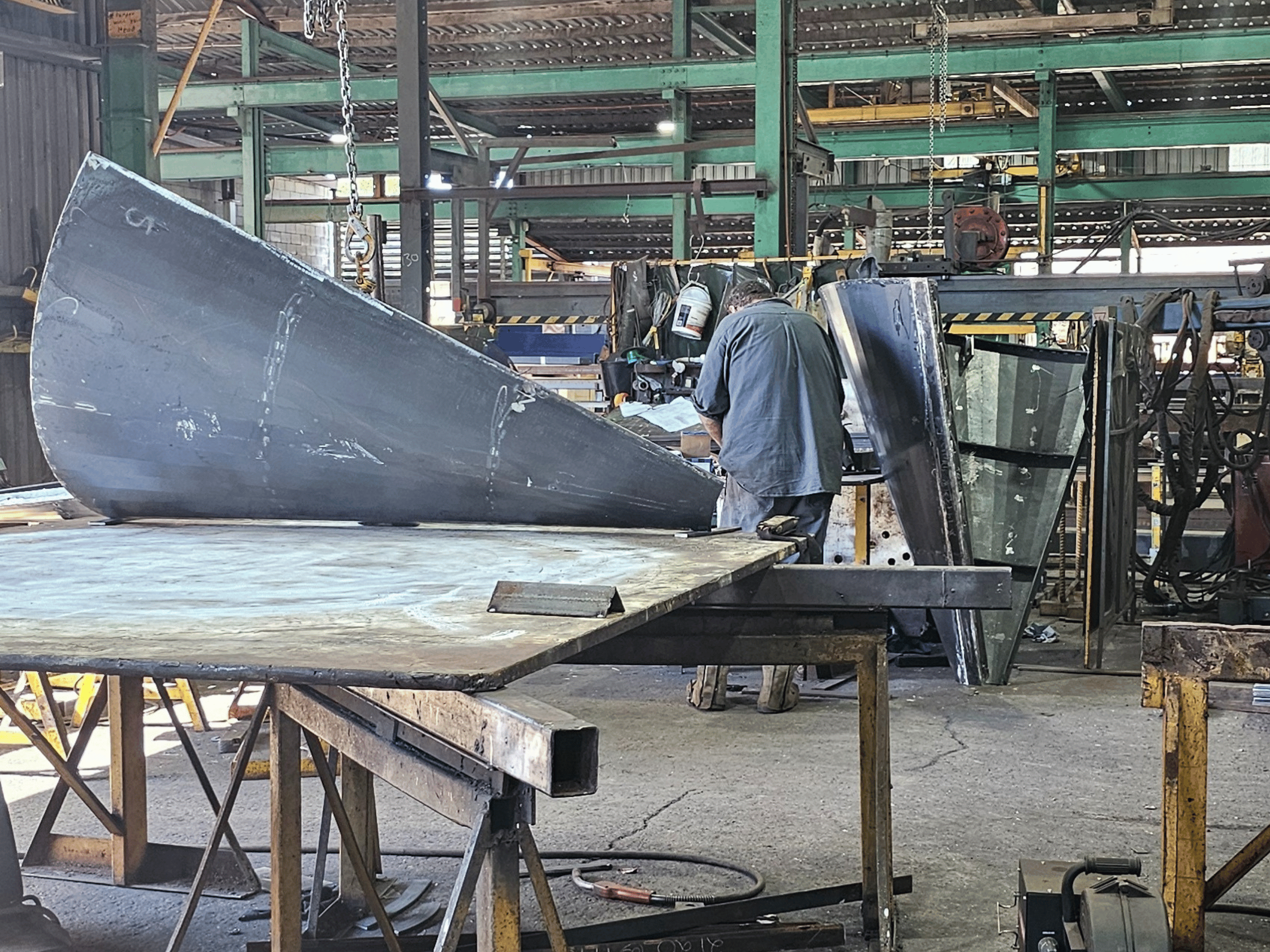

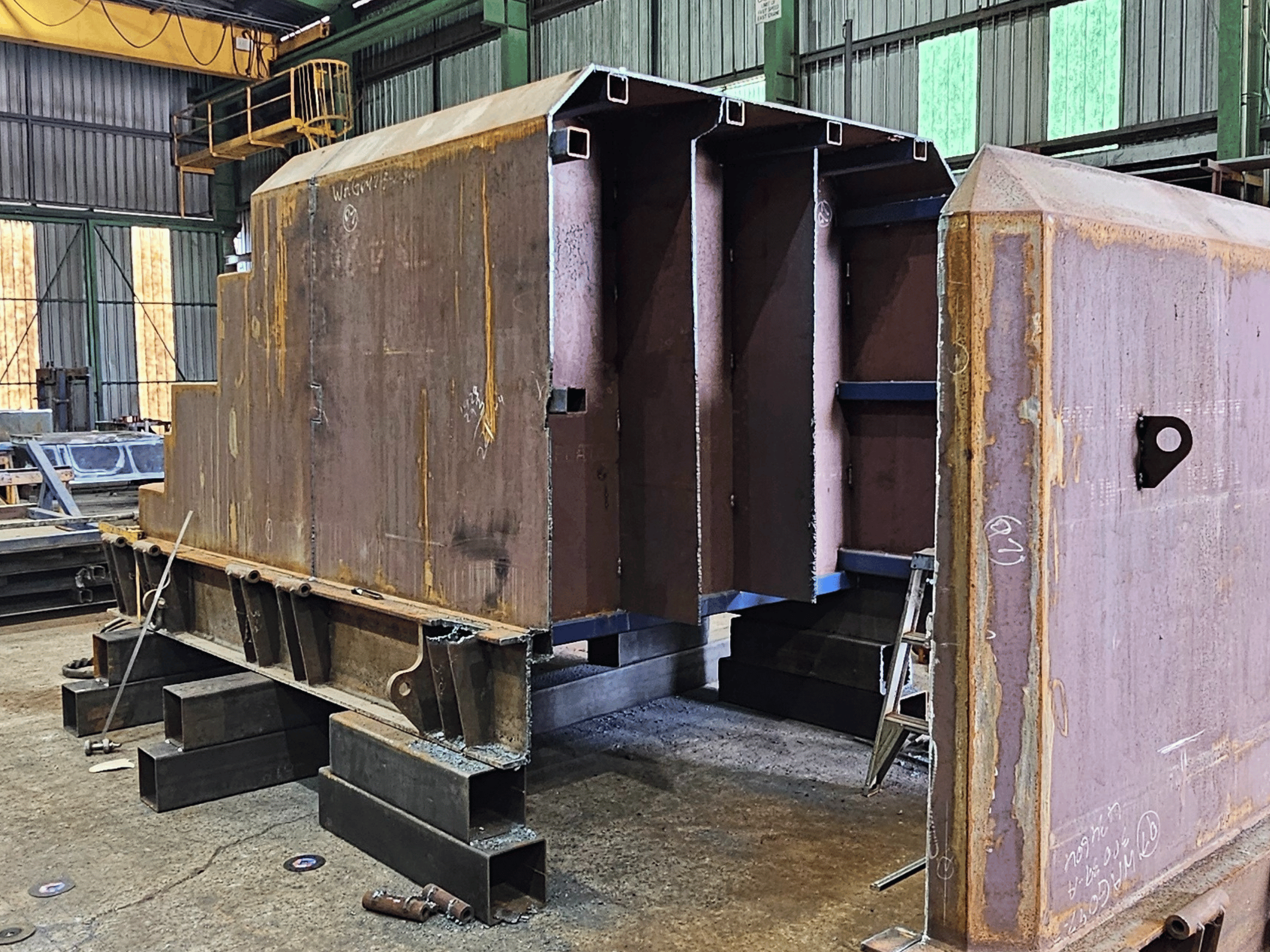

- Irregular or non-rectilinear shapes (e.g. circular pump wells or tapered pits)

- Tight working areas or constrained excavation zones

- Heavy-duty reinforcement requirements

- High hydrostatic pressure from deep pours

- Integration with precast or in-situ components

In these cases, off-the-shelf modular systems may not provide the tolerances or durability required.

2. Weigh up the Material Options

Each formwork type has strengths and limitations. Understanding these early can save time and money on site.

Timber Formwork

- Cost-effective upfront

- Easy to modify on site

- Limited durability, especially in wet or heavy-duty conditions

- Often single-use, prone to warping or failure under pressure

Plastic or Polypropylene Formwork

- Lightweight and corrosion-resistant

- Ideal for smaller, repetitive shapes

- Lacks strength for deep or complex pours

- Difficult to customise on site

Modular Aluminium Formwork

- Fast to assemble

- Reusable for standard, repeatable shapes

- Not suitable for irregular or highly specific applications

- Limited load capacity for deep pits or large pours

Steel Formwork

- High structural strength and dimensional accuracy

- Designed for complex, custom applications

- Long-lasting and highly reusable

- Heavier to handle

- Higher initial investment, often offset by long-term savings

3. Consider Reusability and Lifecycle Cost

While upfront costs are important, long-term value often depends on how many times a formwork system can be reused. Steel formwork offers excellent durability and maintains its structural integrity across multiple uses, especially in harsh site conditions or heavy pours. For contractors delivering repeated scopes steel is a dependable option that avoids the waste and downtime associated with single-use materials.

DWW Engineering also offers modular designs, such as adjustable collars or bolt-on risers, giving clients flexibility without compromising quality or performance. Over time, steel often proves more cost-effective than timber or plastic alternatives, particularly when accuracy and reusability are critical.

4. Assess Site Conditions and Installation Requirements

Your formwork needs to match the build environment as much as the structure itself. Consider:

- How the formwork will be delivered, lifted and installed

- Whether there’s space to stage components

- How many people are required to set it up

- Whether the system can be stripped and reused easily

Pro tip: Check with your manufacturer if they offer trial-assemblies. Trial-assemblies help identify any issues before your structure gets delivered to site, saving you time and money.

5. Prioritise Safety from the Start

Safety is always a priority on site and poorly built or poorly fitted formwork can introduce serious risks. Selecting a formwork system that’s accurately designed and structurally sound helps prevent common issues such as blowouts, misalignment, or inadequate concrete coverage. Steel systems, when fabricated to spec, require less temporary bracing and reduce manual adjustments during installation.

They also help achieve more consistent finishes, which is especially important when dealing with infrastructure assets that require regular inspection. At DWW Engineering, we take safety seriously, designing our formwork systems with installation, stripping, and overall site safety front of mind.

Summary

Choosing the right formwork system isn’t just about price – it’s about selecting a solution that fits your structure, your site, and your team. For complex infrastructure projects, steel formwork often delivers the best balance of performance, durability, and long-term value.